This year, China's die-casting industry has placed a stronger emphasis on scientific research and technological innovation. The investment in both human and material resources has been steadily increasing, reflecting a growing commitment to modernization and efficiency. With recent advancements in technology, the die-casting sector is poised for even greater growth and transformation.

Compared to traditional die-casting processes, the new generation of hardware and electrical automation systems uses robotic manipulators controlled through a human-computer interaction interface. These systems enable full automation under computer control, resulting in higher product quality, reduced labor costs, and improved production efficiency. Additionally, this technology helps alleviate the labor shortage in the die-casting industry, as it reduces the physical strain on workers and improves working conditions.

By adopting such advanced automation solutions, Chinese die-casting companies are not only enhancing their competitiveness but also paving the way for sustainable development. As the industry continues to evolve, the integration of smart manufacturing technologies will play a crucial role in driving long-term growth and innovation. The widespread adoption of these systems is expected to significantly contribute to the overall advancement of China’s manufacturing sector.

This year, China's die-casting industry has placed a stronger emphasis on scientific research and technological innovation. The investment in both human and material resources has been steadily increasing, reflecting a growing commitment to modernization and efficiency. With recent advancements in technology, the die-casting sector is poised for even greater growth and transformation.

Compared to traditional die-casting processes, the new generation of hardware and electrical automation systems uses robotic manipulators controlled through a human-computer interaction interface. These systems enable full automation under computer control, resulting in higher product quality, reduced labor costs, and improved production efficiency. Additionally, this technology helps alleviate the labor shortage in the die-casting industry, as it reduces the physical strain on workers and improves working conditions.

By adopting such advanced automation solutions, Chinese die-casting companies are not only enhancing their competitiveness but also paving the way for sustainable development. As the industry continues to evolve, the integration of smart manufacturing technologies will play a crucial role in driving long-term growth and innovation. The widespread adoption of these systems is expected to significantly contribute to the overall advancement of China’s manufacturing sector.

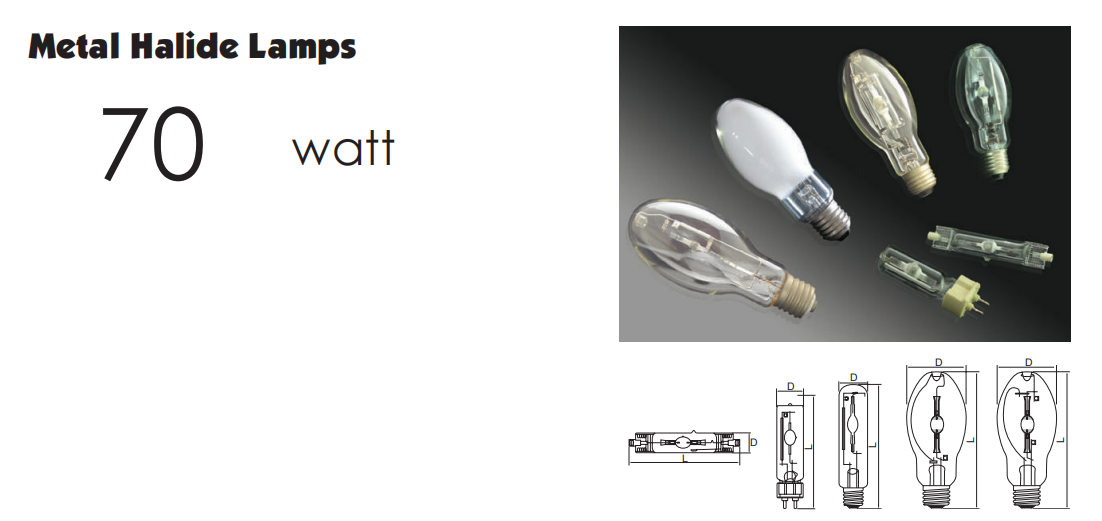

Metal Halide Bulb

A Metal Halide Bulb, also known as a Metal Halide Lamp, is a type of gas discharge lamp that produces light by passing electrical currents through a mixture of mercury and metal halides. It is known for its high luminous efficacy, long lifespan, and good color rendering index, making it a popular choice for various industrial and commercial applications

4

Key Features

- High Luminous Efficacy: Achieves light efficacy ranging from 65 to 140 lm/W.

- Long Lifespan: Typically lasts between 5000 to 20,000 hours.

- Good Color Rendering: Provides a high color rendering index (Ra) of 65 to 95, offering accurate color representation.

- Compact and Stable Design: Available in quartz and ceramic versions, offering structural stability and durability.

Applications

Metal Halide Bulbs are widely used in:

- Stadiums and Sports Arenas: For their high output and ability to provide optimal lighting conditions.

- Construction Sites: Ensuring safety and visibility during nighttime operations.

- Parking Lots and Loading Docks: Providing bright, consistent lighting for extended periods.

- Commercial Buildings: Enhancing the aesthetic appeal and functionality of indoor spaces

.7

metal halide bulb,400 watt metal halide bulb,250 watt metal halide bulb,1000 watt bulb,100 watt metal halide bulb

Yangzhou M.T. New Energy & Lighting Group Co., Ltd. , https://www.mtstreetlight.com