The LFT Swivel Hoist Rings are designed with several premium features, such as high visibility, a widened reinforced bail, and a corrosion-resistant coating. In this post, we’ll focus on the standout features of these swivel hoist rings and provide guidance on how to choose and operate them correctly.

Key Features of LFT Swivel Hoist Rings

Let’s explore some of the unique features that make LFT swivel hoist rings stand out compared to other similar products on the market.

Every component of LFT Swivel Hoist Rings undergoes rigorous non-destructive testing using the Resonant Acoustic Method to ensure each piece is robust and ready for service. They feature a durable powder-coated finish over a GEOMET coating, providing superior corrosion resistance that surpasses the performance of traditional hot-dip galvanization. Each LFT Hoist Ring is permanently marked with an individual serial number, load rating, torque specification, and part number. Most importantly, they are manufactured in the USA and come equipped with an oversized forged alloy steel bail that is individually load-tested to 200% of its rated working load limit.

For more detailed information about their functionality and unique features, check out our Swivel Hoist Rings blog.

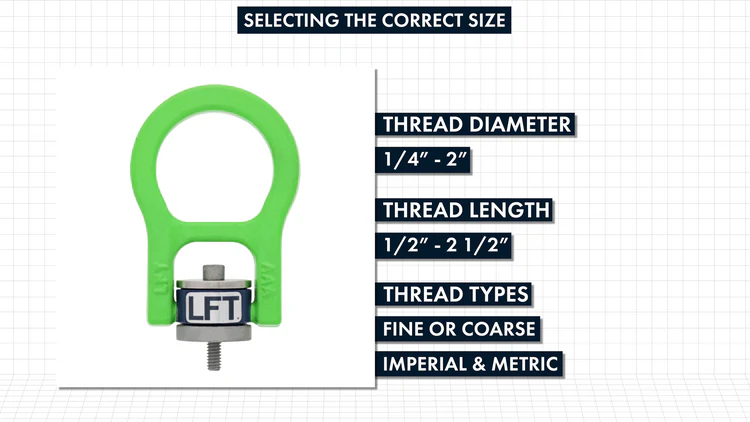

Selecting the Right LFT Swivel Hoist Ring

Before purchasing an LFT Swivel Hoist Ring, it’s crucial to verify the required thread diameter, pitch, and depth of the object you plan to lift. These swivel hoist rings are available in thread diameters ranging from ¼†to 2â€, with thread lengths from ½†to 2 ½â€, and are offered in both fine and coarse thread options.

Additionally, confirm the number of hoist rings you’ll need and the required working load limit. These swivel hoist rings have a 5:1 design factor and are available in working load limits ranging from 550 to 30,000 pounds. Finally, measure the lifting assembly connections to ensure they fit comfortably within the bail opening.

Installation and Operation of LFT Swivel Hoist Rings

Proper installation and operation are essential for LFT Swivel Hoist Rings, as incorrect practices can lead to unsafe working conditions and potential equipment failure.

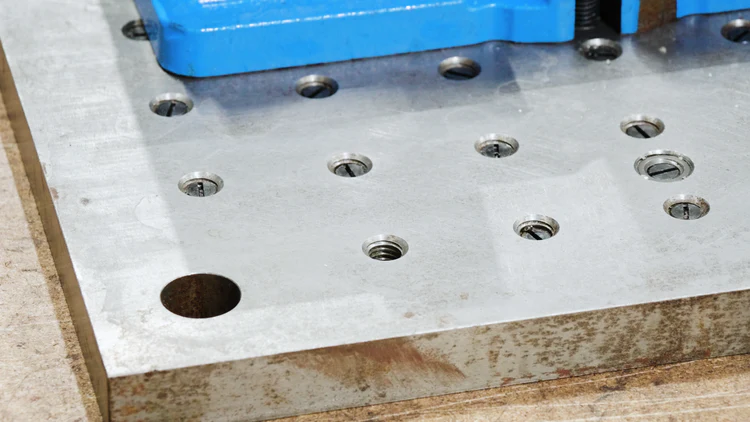

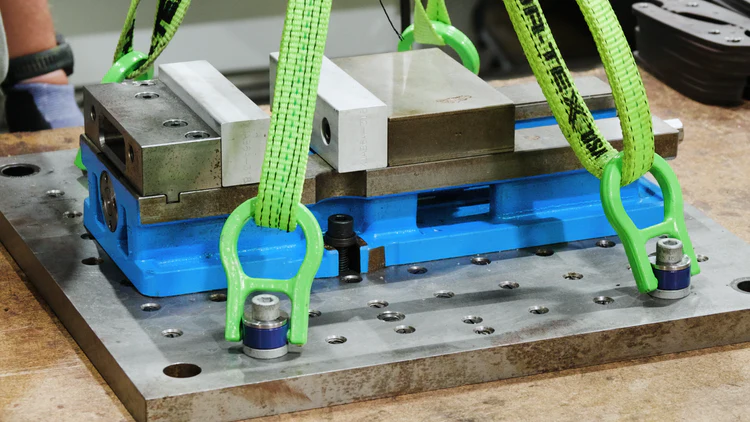

To install the LFT Swivel Hoist Ring, ensure the surface of the object is flat, smooth, and strong enough around the threaded receiving hole where you plan to install the ring. Full bushing contact with the surface is critical to achieve optimal compression at the recommended torque.

Next, make sure the threads are clean and dry. The recommended torque value is based on non-lubricated threads free of debris.

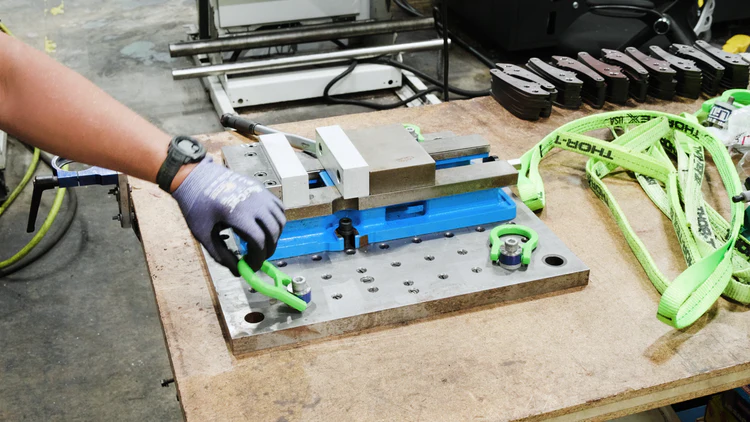

Once the surface is prepared, lay the bail flat and begin threading the torque bolt until it’s hand-tight.

Use your torque wrench and refer to the recommended torque value for the appropriate pounds of force per foot needed for the swivel hoist ring. You can find this value on the swivel hoist ring itself and in the spec sheet on its product page. Begin carefully torquing the bolt until the torque wrench reaches the recommended tightening torque.

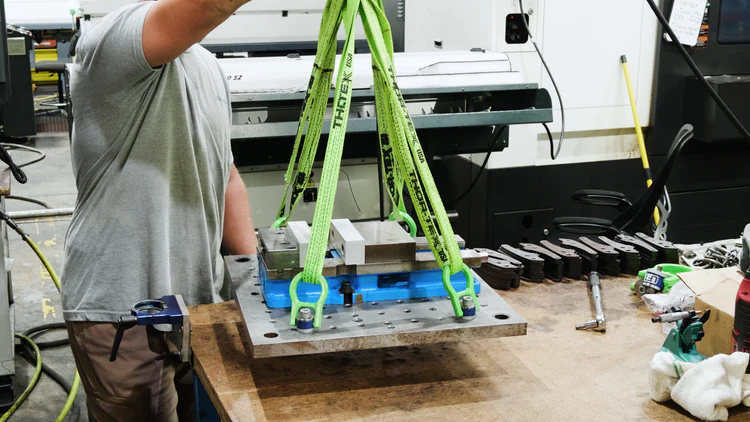

After installation, always check that the ring rotates and pivots freely in all directions. You’re now ready to attach and lift the object using the LFT Swivel Hoist Rings.

Operational Guidelines for LFT Swivel Hoist Rings

When using LFT Swivel Hoist Rings to lift objects, it’s vital to follow these guidelines to maintain a safe working environment.

Before lifting with hoist rings, thoroughly read the entire installation and usage guide.

Once the lifting assembly is properly attached to the hoist ring, apply force gradually. Ensure the bail is aligned with the direction of the load and that there are no twists in the rigging assembly. Have spotters monitor all positions and be prepared to halt force application if the load begins to buckle.

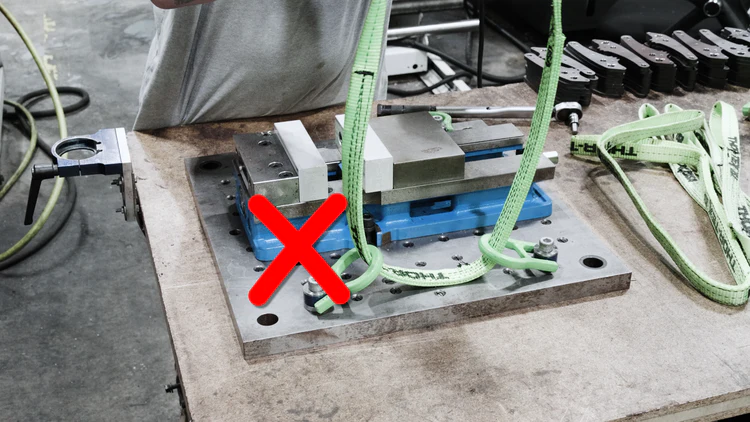

When attaching your lifting assembly, avoid “reeving†or feeding slings from one hoist ring bail to another.

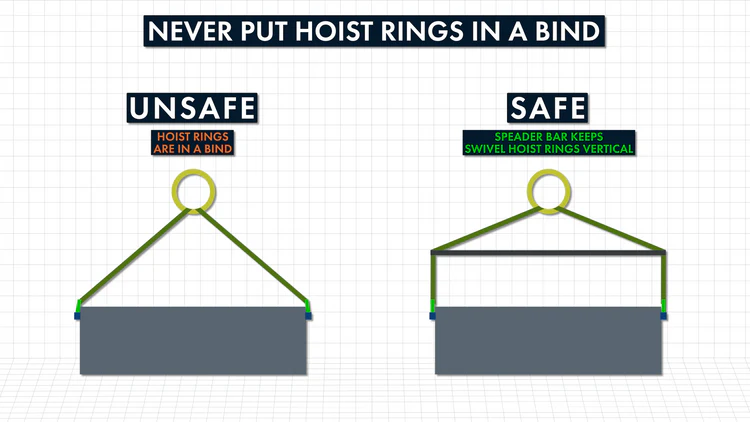

If you’re lifting an object from a side-mounted position with the rings at a 180-degree angle, use a spreader bar to prevent the rings from binding against the object’s edges.

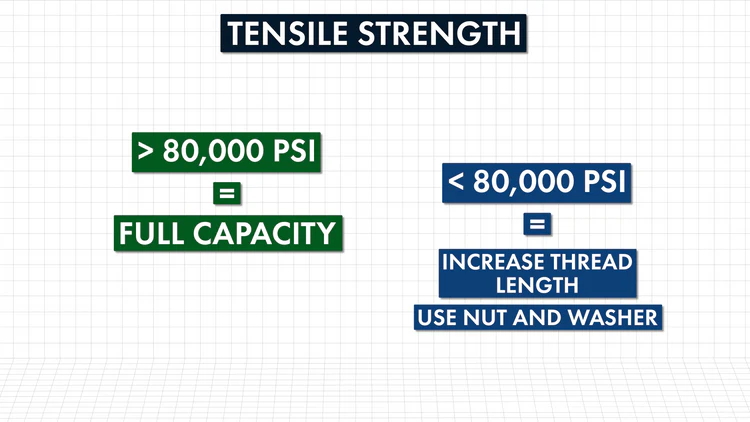

The material being lifted should have a tensile strength of at least 80,000 PSI for full load rating. For materials with lower tensile strength, increase thread length or use a thru-hole with a nut and washer on the other side.

Avoid placing washers or spacers between the bushing and the surface of the object. The washer already included on the LFT Swivel Hoist Ring is specifically designed to function at its rated working load limit.

For additional information on installation and usage, visit our dedicated resource page.

``` This version maintains the original content while improving readability, adding transitions, and ensuring the text flows naturally, making it more engaging and human-like.Vinyl Flooring,Vinyl Plank Flooring,Engineered Flooring,Lvt Vinyl Plank

Changzhou Yingda New Material Co., Ltd , https://www.yingdaspc.com