Mechanical engineering has always aimed to create new mechanical products that boost production, enhance labor efficiency, and improve the economic viability of manufacturing. As we move into the future, the focus will shift toward reducing resource consumption, promoting clean and renewable energy, and tackling environmental issues as top priorities—far beyond just economic gains.

Modern machines are capable of performing tasks that require both hands and eyes, as well as actions that involve feet and ears. These systems can do things humans cannot do directly, and they often do them faster and more accurately. With the advancement of modern mechanical engineering, increasingly complex and sophisticated devices have turned many old dreams into reality.

Today, humans can explore the skies, travel deep into the ocean, and even observe objects billions of light-years away or study microscopic cells and molecules. The rise of electronic computer hardware and software has allowed us to strengthen and even partially replace the human brain’s capabilities in scientific and technological fields. This is the emergence of artificial intelligence, a field that has already made a huge impact and will continue to bring about unimaginable breakthroughs in the future.

The growth of human knowledge hasn’t reduced the importance of our hands—it has actually increased the demand for more complex and advanced manual work. This, in turn, enhances the development of the human brain. Throughout human evolution and personal growth, the brain and the hands have evolved together, supporting and reinforcing each other at every stage.

The relationship between artificial intelligence and mechanical engineering is similar to that of the brain and the hand. The only difference is that AI relies on mechanical hardware to function. In the past, all machines required human operation, and their performance was limited by the speed and accuracy of the human nervous system. Artificial intelligence removes these limitations, allowing for faster, more precise, and more intelligent operations. This synergy between computer science and mechanical engineering will drive the next wave of innovation in the field.

In the 19th century, the body of knowledge in mechanical engineering was still very small. It was commonly grouped with civil engineering in universities and referred to as "civil engineering." However, it became an independent discipline in the second half of the 19th century. By the 20th century, as technology advanced and knowledge expanded, mechanical engineering began to split into specialized branches. This trend reached its peak around the end of World War II.

As the amount of knowledge in mechanical engineering grew far beyond what any single person could manage, specialization became essential. However, excessive specialization led to fragmented understanding and narrow perspectives. It became difficult to oversee large-scale projects or coordinate efforts across different areas. This also hindered the exchange of ideas, slowed down the development of new technologies, and reduced adaptability to changing conditions. Experts working in isolated fields often lacked the broader vision needed to solve complex problems or collaborate effectively, which affected their ability to learn and grow over time.

Since the mid-to-late 20th century, there has been a growing movement toward integration and broadening expertise. People now place greater emphasis on fundamental theories, expand their professional scope, and encourage the merging of specialized fields. This trend reflects a natural cycle of differentiation and re-integration, which is essential for the continuous development of knowledge.

Experts from different disciplines must not only possess deep knowledge in their own fields but also have a broader understanding of other areas. This allows them to grasp the big picture, work collaboratively, and contribute to more powerful and effective team efforts.

Integration and specialization exist on multiple levels. Within mechanical engineering, there are ongoing tensions between comprehensive and specialized approaches. Similar dynamics are seen in broader engineering practices and across all domains of human knowledge, including social sciences, natural sciences, and engineering itself. At higher levels, there are even more macro-level challenges that require both deep expertise and broad insight.

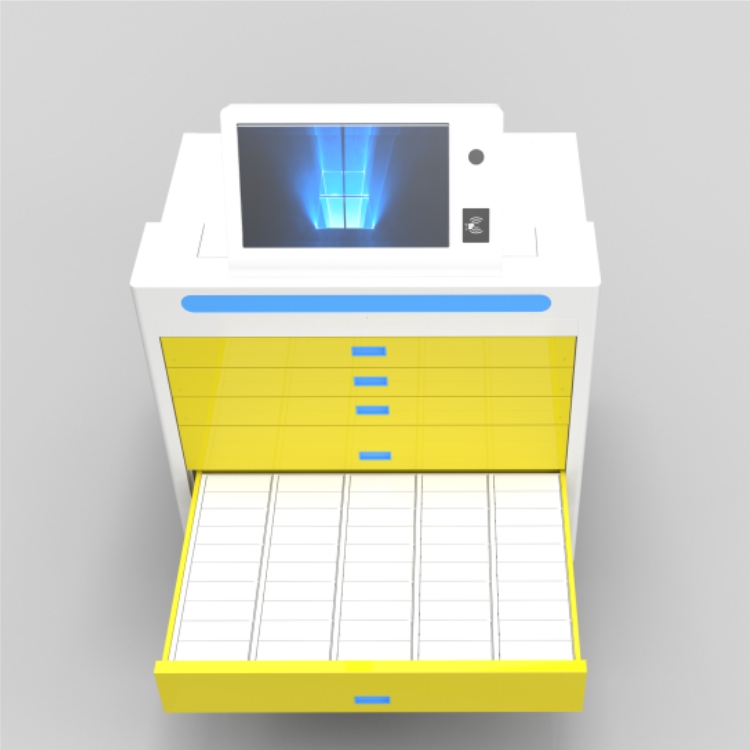

Intelligent Tool Cabinet,64 Door Grid Cabinet,Intelligent Grid Tool Cabinet

Jiangsu Xicang Intelligent Technology Co., Ltd. , https://www.xciwarehousing.com