A CNC drilling machine is essentially a specialized tool designed primarily to create holes in workpieces using drill bits. Its applications span across drilling, reaming, countersinking, and tapping operations. Given the critical role of the drill bit as a key component, proper usage becomes paramount. Here are some essential considerations to keep in mind:

Firstly, ensure the concentricity between the spindle and the spring chuck, along with the clamping force of the latter. Poor concentricity can lead to breakage of smaller drill bits or misalignment with larger ones. Insufficient clamping force may cause the drill bit's rotational speed to deviate from the set value, leading to slippage between the chuck and the bit.

Secondly, when clamping a fixed-handle drill bit in the spring chuck, the recommended clamping length should be four to five times the diameter of the drill bit to achieve optimal stability.

Thirdly, regularly inspect the spindle press foot. The contact surface must remain horizontal and perpendicular to the spindle without any wobbling. This prevents issues like skewed or incorrectly positioned holes during drilling.

Fourthly, the vacuum system of the drilling machine plays a crucial role. Adequate vacuum suction helps cool the drill bit while simultaneously removing debris, reducing friction and preventing overheating.

Fifthly, always source drill bits from reputable manufacturers. Upon arrival at your facility, inspect them thoroughly, ensuring at least 4% comply with regulations. Additionally, employ a 10-15x magnification microscope to examine every single bit for defects such as gaps, abrasions, or cracks.

Sixthly, timely resharpening of drill bits can significantly enhance their lifespan, reducing production costs. Typically, using a tool microscope, the wear depth should not exceed 0.2mm across the total length of both main cutting edges. When resharpening, remove approximately 0.25mm. Standard fixed-handle bits can usually be resharpened three times, whereas those with shank tips can endure two rounds. Overdoing this could compromise drilling quality and accuracy, potentially rendering finished products defective.

Seventhly, discard a drill bit if its diameter decreases by more than 2% compared to its original size.

Lastly, setting appropriate drill bit parameters is vital. While most manufacturers provide a reference table listing drilling speeds and feeds, these figures should serve merely as a guide. Experienced operators often adjust these settings based on real-world conditions. Although there might be slight discrepancies between actual and recommended values, they typically aren't significant.

Adhering to these guidelines can prolong the life of your drill bits, produce precise holes, and cut down on avoidable expenses. Hopefully, these tips help improve your experience with CNC drilling machines. For purchasing inquiries, feel free to reach out via our website. Please note that this content is adapted from online sources and provided solely for informational purposes.

Wind Energy Fasteners Supplier China, Yokelink

sales@yokelink.com

Yokelink has been supplying fasteners for the wind energy industry for over 10 years. These fasteners are utilised in producing a gearbox, a valuable wind mill turbine component located within the nacelle. we also offer standard wind power energy fasteners in line with ISO or DIN, including vibration-resistant security products. Wind tower bolt plays a important role as joining components in fastening different parts of wind turbine tower, Yokelink is a professional manufacturer which supplies high grades fasteners 8.8-12.9 for wind tower projects.

Product Ranges:

We currently service all aspects of the wind turbine market, Our extensive range allows wind

turbine manufacturers to 'single source'all their fastener requirements with all the advantages that this brings, providing a range of fasteners, both standard and customer bespoke for:

turbine manufacturers to 'single source'all their fastener requirements with all the advantages that this brings, providing a range of fasteners, both standard and customer bespoke for:

â—Foundation

â—Tower Construction

â—Blade to Hub

â—Nacelles

â—Off-shore Transition Pieces

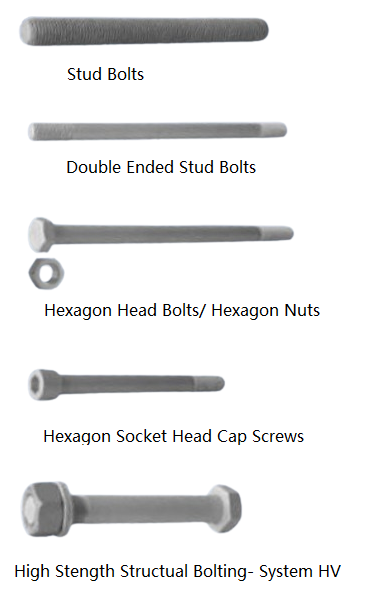

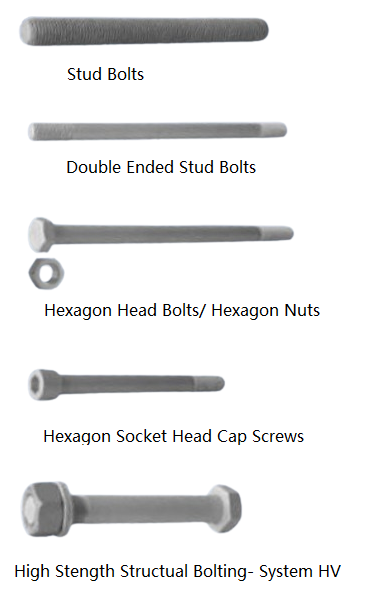

Hex cap screws DIN 931, DIN 933 and ISO 4017

Hex Bolts and Nuts, size M10-M64

Stud Bolts size M12-M64

Threaded Rods size M10-M64

Tower Flange Bolts size M10-M64

WHAT ARE WINDMILL POWER FASTENERS?

WHAT ARE WINDMILL POWER FASTENERS?

Fasteners used in wind power tower and blade connection and transmission, including hex bolts, stud bolts, tower flange bolts, foundation bolts, threaded rods, high strength double head screw, hardened and structural bolts, nuts, washers and threaded rods, and hex cap screws etc.

WHAT'S THE CHARACTERISTICS OF WIND POWER FASTENERS

High strength, high grade and precision, can work in hard conditions like extremely hot and cold environment and corrosion resisted .In wind turbine generator system, because of the randomness of power source, hardness of operating circumstances, special producing and installing, as well as high costs of maintaining, the requirements for wind turbine bolts would be extremely high. We have to take effective actions to ensure the reliability of the bolts connection, from the bolts structure design, manufacture process to production and assembling.

WHAT BOLTS ARE USED IN A WIND TURBINE?

Wind turbine bolts, there are wind turbine blade bolts, wind turbine anchor bolts, wind turbine foundation bolts, high strength and high tension hexagon head bolts, nuts and washers are mainly used for wind turbine.

HOW MANY BOLTS ARE IN A WIND TURBINE?

A most common 3 blades wind turbine requires almost 25,000pcs fasteners. With the rapid increase of wind energy demand in the worldwide, the fasteners for wind turbine and energy increased greatly as well. Most high strength bolts used for wind turbine are grade 10.8, grade 12.9 and the coatings are also very crucial, Dacromet are most commonly coating in wind turbine fasteners.

A most common 3 blades wind turbine requires almost 25,000pcs fasteners. With the rapid increase of wind energy demand in the worldwide, the fasteners for wind turbine and energy increased greatly as well. Most high strength bolts used for wind turbine are grade 10.8, grade 12.9 and the coatings are also very crucial, Dacromet are most commonly coating in wind turbine fasteners.

When you need Wind Power Fasteners, refer to above our catalog. We offer them in a full selection of sizes, provide the diameter or part number to get a quote of wind power fasteners, leave your message, or send us an email. You can also call us to get answers to your questions and place your order.

Wind Energy Fasteners Supplier China, Yokelink

sales@yokelink.com

Wind mill ,Wind Power fasteners, Wind mill Turbine, Stud Bolt, windmill energy, house wind turbine, Wind Turbine Blades

Ningbo Yokelink Machinery Co.,Limited , https://www.yokelink.com